Technical support

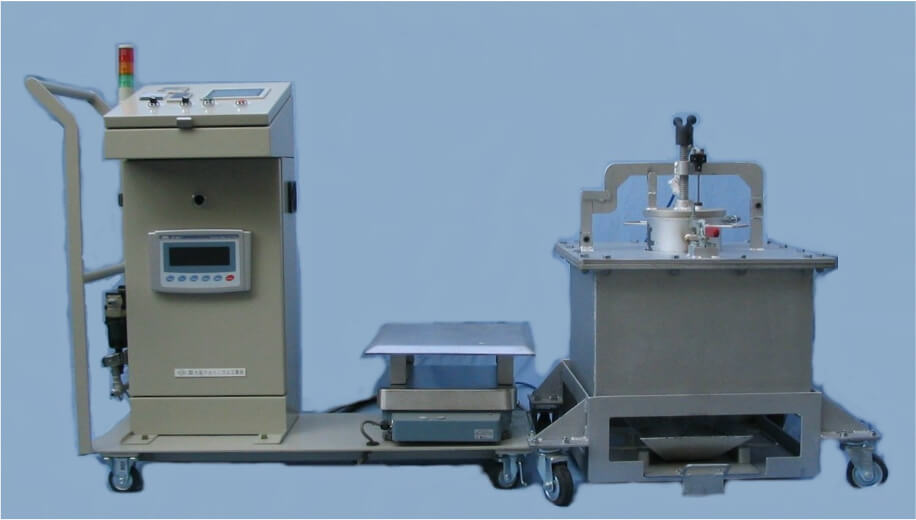

DIK molten aluminium alloy cleanliness evaluation apparatus

This system measures the cleanliness of molten aluminium (fewer inclusions is better).

Features

1

When the test samples are homogeneous, reproducibility is high, and variations are small.

(For low-cleanliness molten aluminium, samples are less likely to be homogeneous, and there may be some variation.)

Table. AD12.1 in DIK Shirakawa Plant

| Sample | Residue rate (%) |

|---|---|

| 1 | 0.85 |

| 2 | 0.79 |

| 3 | 0.81 |

| 4 | 0.90 |

| 5 | 0.93 |

| Average | 0.86 |

| Standard deviation | 0.056 |

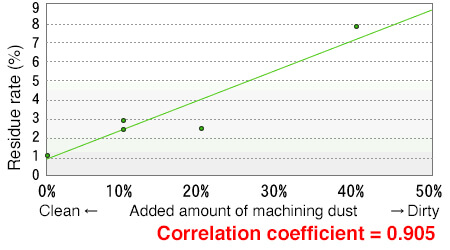

2

High correlation

3

Testing is easy.

(Measurement of the number of inclusions, etc., in the microstructure is not necessary.)

4

Data do not depend on the measurer.

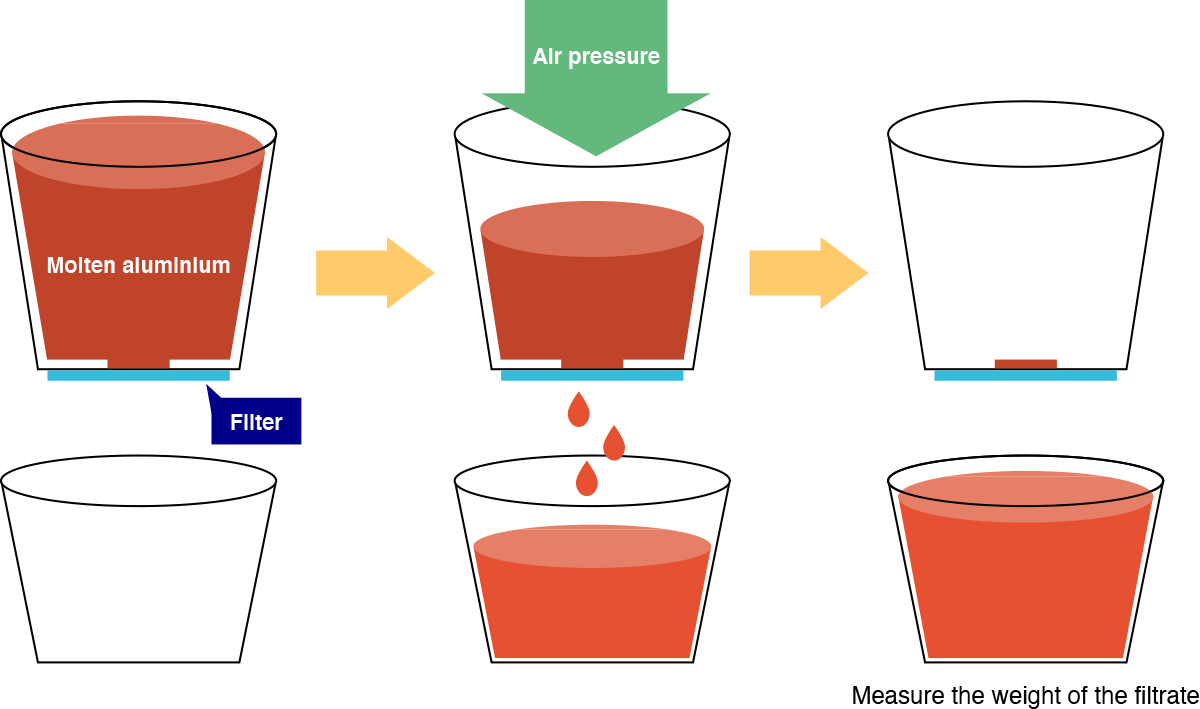

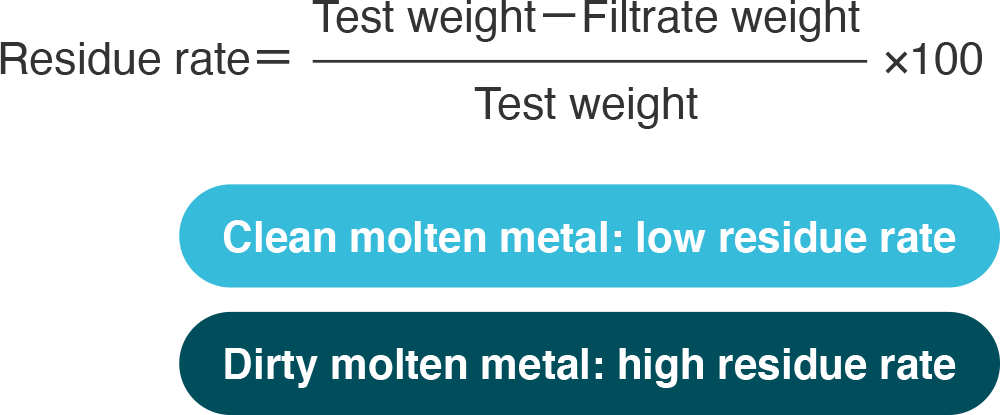

Measurement principles

The sample and filtrate weights are measured to calculate the residue rate with the formula below.

Test weight: weight of the test ingot

Filtrate weight: weight of the filtered molten metal