CR-1 alloy

- Aluminium alloys

- Aluminium alloys for high pressure die casting

- Developed alloys

- Automobiles and motorcycles

- Various on-vehicle parts

- Precision equipment

- Electrical parts

In terms of composition, this is an Al-Si-Mg-Fe-Cr alloy

Features

1

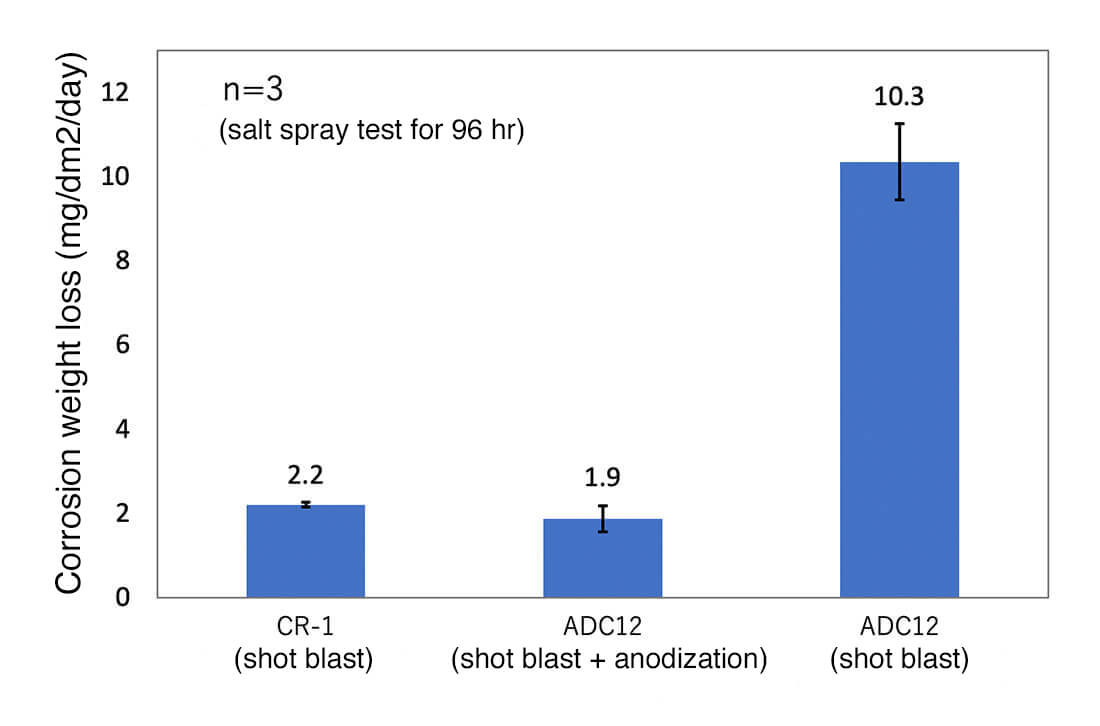

This alloy has high corrosion resistance. (Graph 1; Photo 1)

- A salt spray test (for 96 hr) demonstrated that CR-1 has the same corrosion resistance as ADC12 anodized items.

2

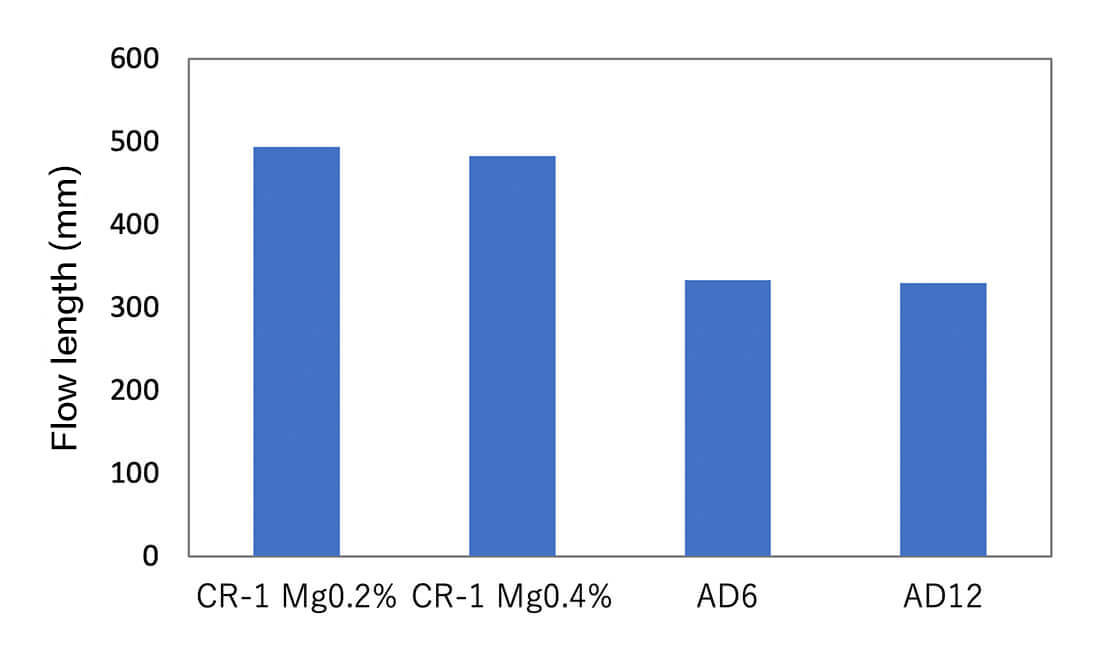

Its liquidus temperature is low, and it also has good castability. (Table 1; Graph 2)

- The addition of Si results in high fluidity.

- The addition of Fe and Cr prevents from sticking to the die.

Table 1. Compositions and liquidus temperatures for each alloy

| Alloy name | Cu | Si | Mg | Fe | Cr | Liquidus temperature (°C) | Test temperature (°C) |

|---|---|---|---|---|---|---|---|

| CR-1 | 0.00 | 12.38 | 0.19 | 0.21 | 0.20 | 582 | 682 |

| 0.00 | 12.40 | 0.39 | 0.21 | 0.20 | 582 | 682 | |

| AD6 | 0.02 | 0.54 | 3.55 | 0.50 | 0.03 | 635 | 735 |

| AD12 | 1.90 | 10.76 | 0.20 | 0.84 | 0.08 | 571 | 671 |

Applications

- Parts requiring high corrosion resistance

-

- Building components

- Shipbuilding parts

- Automobile parts, etc.

CR-1 has been patented.

Remarks

Please note that the figures described in the above technical data are based on our measurements and are not guaranteed.