HT alloys

- Aluminium alloys

- Aluminium alloys for high pressure die casting

- Developed alloys

- Automobiles and motorcycles

- Various on-vehicle parts

- Precision equipment

- Electrical parts

Features

- The Si in HT-1 improves its fluidity and makes it easier to cast.

- The Cu in HT-2 increases its strength.

- The Fe in HT alloys in general helps prevent from sticking to the die.

- Also, HT alloys in general have low levels of impurities to ensure high thermal conductivity.

1

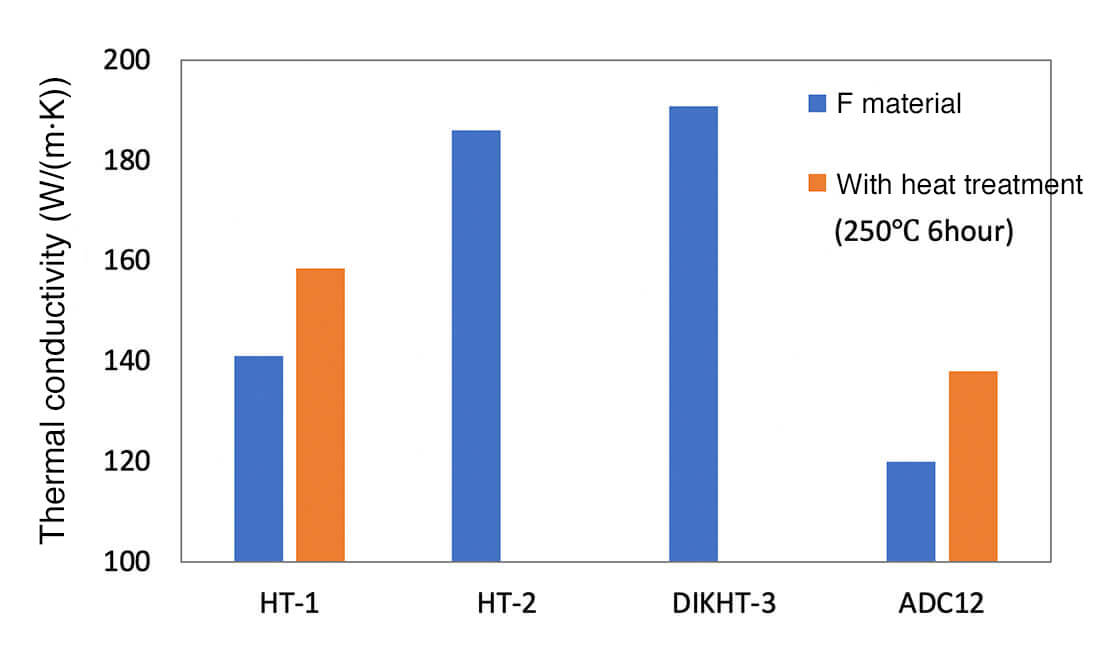

HT alloys provide high thermal conductivity, as shown in Graph 1.

The thermal conductivity of HT-1 can be further increased by heat treatment.

HT-2 and DIKHT-3 provide high thermal conductivity without heat treatment.

2

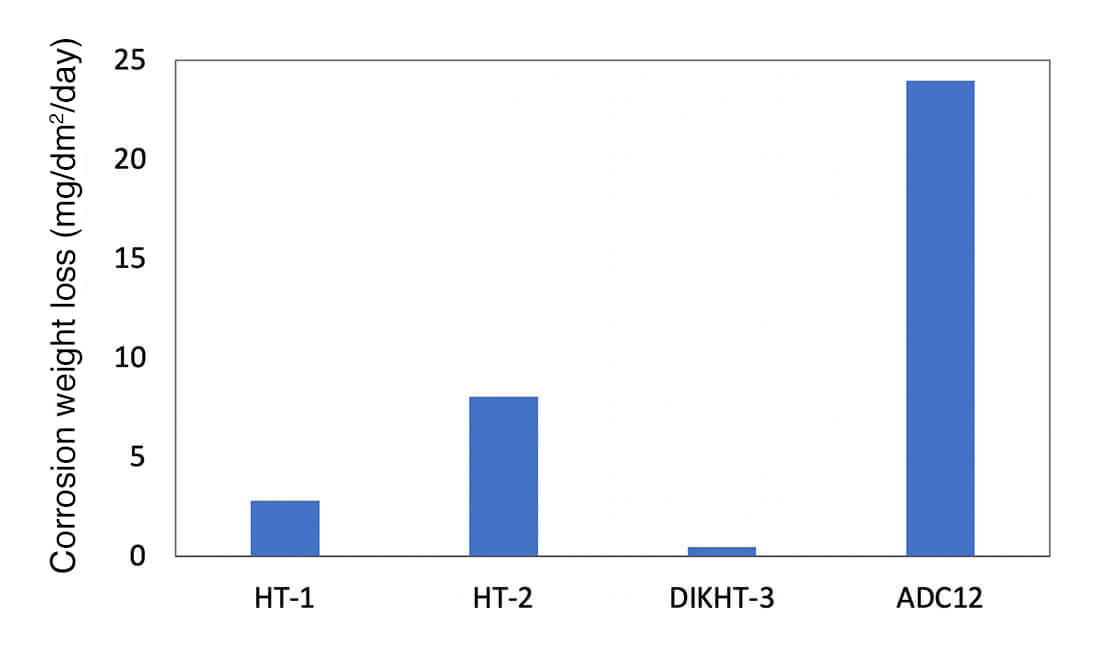

HT-1 and DIKHT-3 provide especially high corrosion resistance, as shown in Graph 2.

3

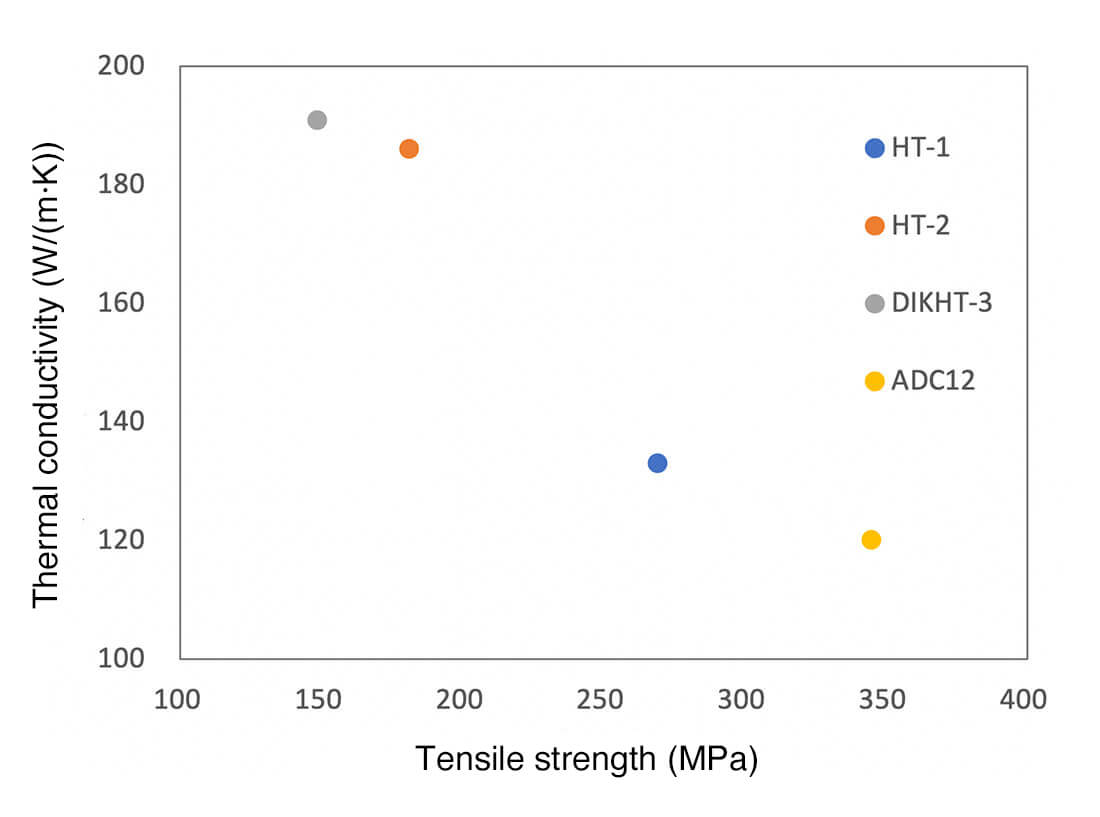

The relationship between thermal conductivity and tensile strength is shown in Graph 3. Tensile strength decreases as thermal conductivity increases.

4

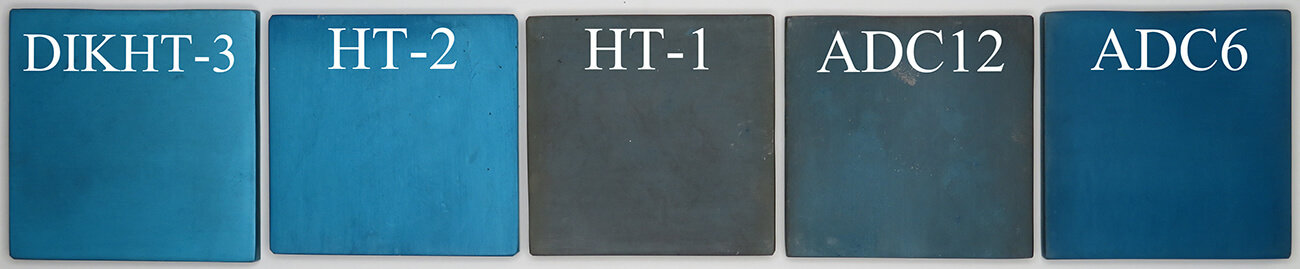

HT-2 and DIKHT-3 can be anodized finely, as shown in Photo 1.

Si improves fluidity and makes the alloys easier to cast.

Fe helps prevent from sticking to the die.

Cu increases their strength.

The alloys have low levels of impurities to ensure high thermal conductivity.

Applications

- Parts that require heat dissipation properties

-

- Heat sinks and heat-receiving blocks for electronic devices

- LED headlights, etc.

HT-2 has been patented.

* DIKHT-3 is covered by the patent for HT-2.

Remarks

Please note that the figures described in the above technical data are based on our measurements and are not guaranteed.