Effective use of resources

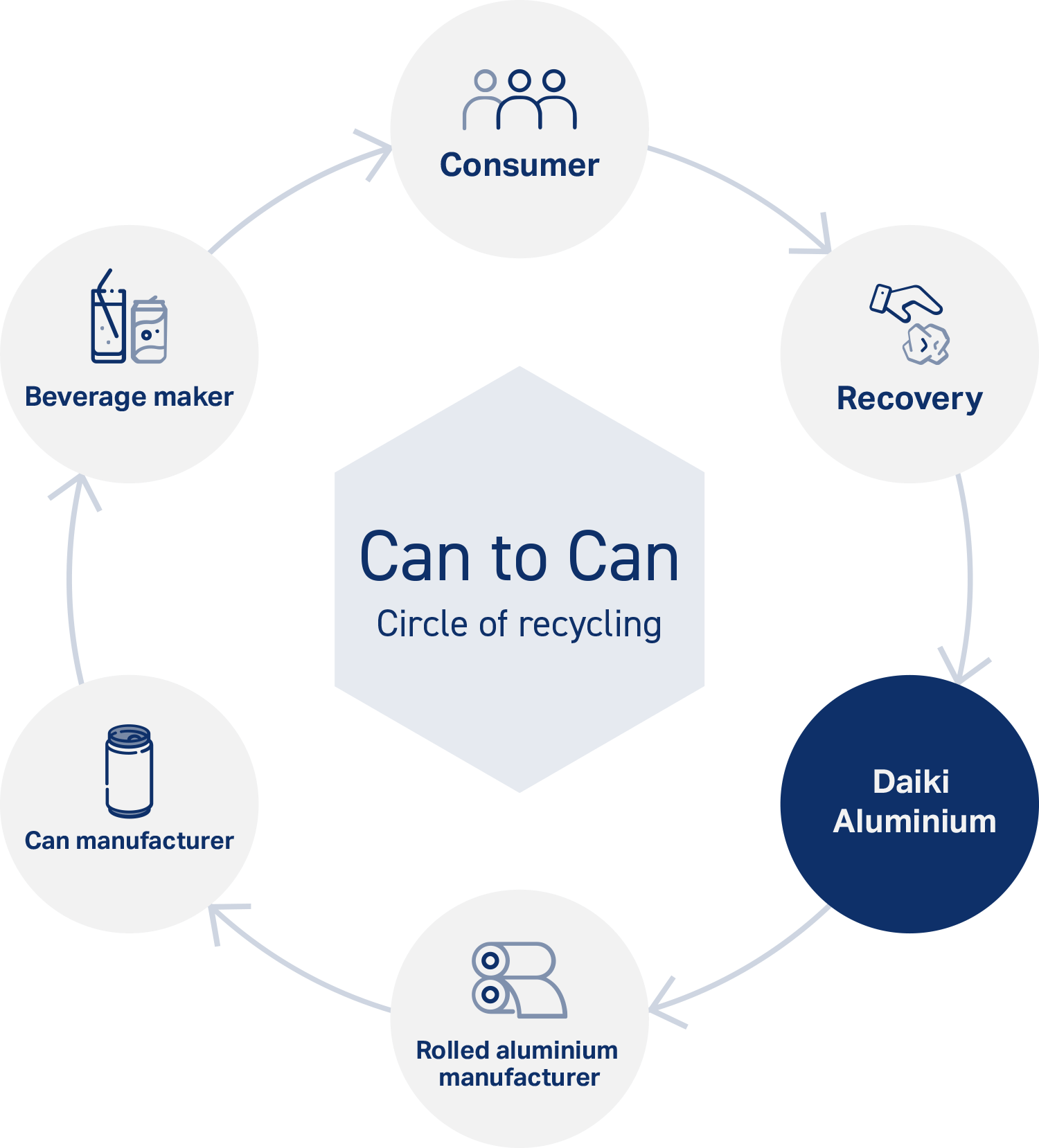

Can to Can

Aluminium cans have the advantage of being infinitely recyclable. In fiscal 2019, the recycling rate was 97.9%*, and the can-to-can rate was 66.9%* (according to the Japan Aluminum Can Recycling Association).

“Can to Can,” which refers to the recycling of used aluminium cans to produce new aluminium cans, has many advantages.

- Recycling of recyclable items like aluminium cans, instead of throwing them away, helps reduce waste.

- The cost of the energy needed to produce ingots from (used) aluminium cans is only 3% of that needed to produce ingots from bauxite, so energy use can be reduced by as much as 97%.

- Aluminium is produced from an ore called bauxite, a precious natural resource with limited reserves on earth.

Recycling is also very important in terms of conserving limited resources.

Many people participate in recycling activities through organizations like schools, children’s associations, and residents’ associations. Daiki Aluminium purchases aluminium cans collected through such activities as “Can to Can” raw materials to further expand the recycling loop.

Sash to Sash

In the aluminium industry, the trend toward the recycling of waste sashes to produce new sashes (material recycling) has been accelerating in recent years.

Our company also introduced X-ray sorting equipment in 2017 as an initiative to improve the quality of sash scrap we use. This new type of machine, which features one of the best aluminium sorting capacities in Japan, enables a rate of removal of foreign matter of 98% and almost perfect sorting.

Furthermore, high-quality scrap is delivered to sash manufacturers as it is, which helps to reduce CO2 emissions from melting and other processes, and we have been recognized by the Japanese Government as a company that promotes the introduction of advanced equipment for CO2-saving recycling.

Effective use of two types of aluminium dross

When the raw materials for aluminium alloys are melted, dross containing a large amount of aluminium rises to the surface of the molten metal. Dross also rises to the surface of the molten metal during the refining process, and this type of dross contains magnesium chloride. These two types of dross, which have different properties, are subjected to different processes and used as valuable resources.

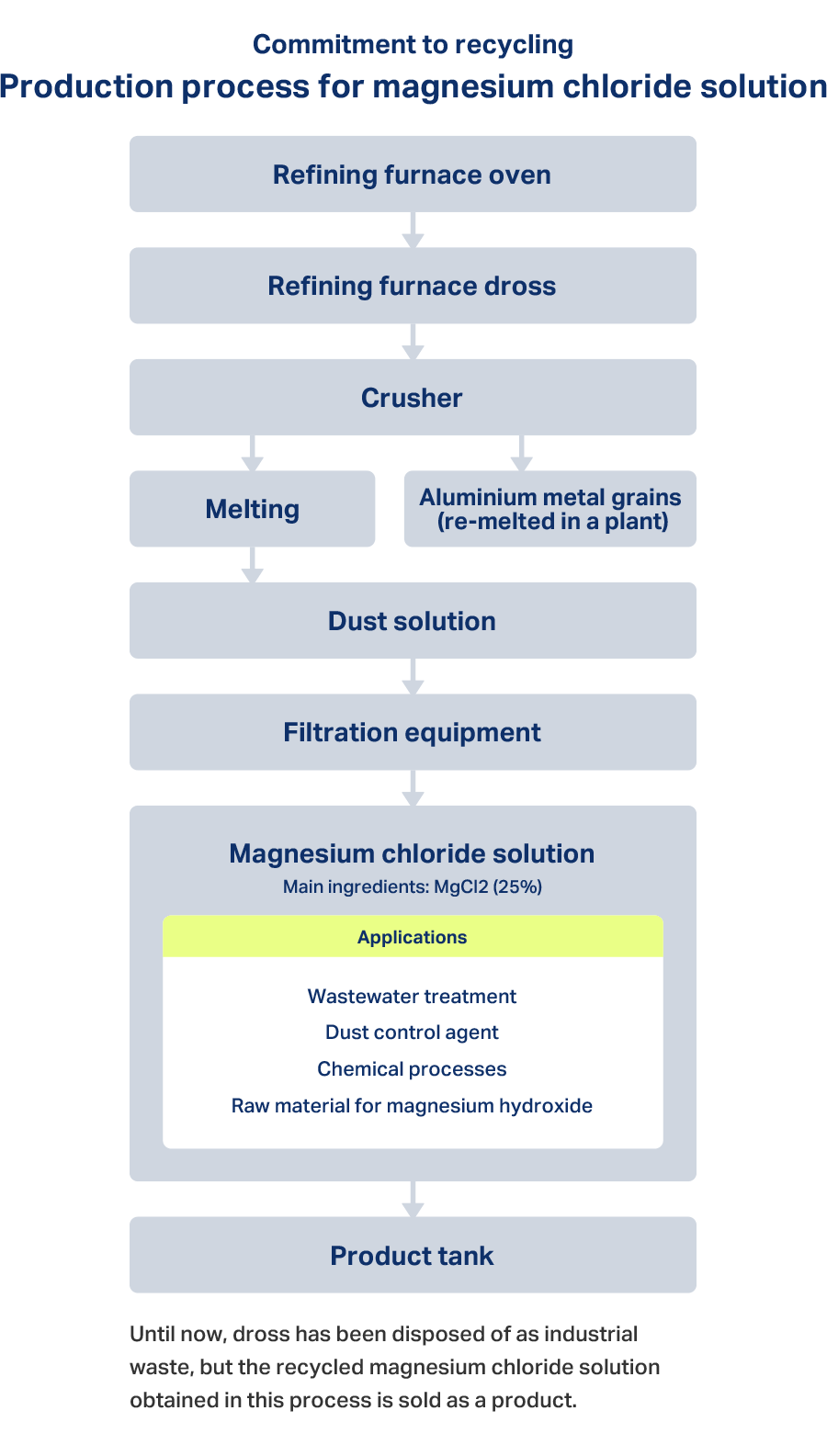

1Liquid magnesium chloride

The process to recycle aluminium scrap involves refining processes for the removal of impurities, degassing of the molten metal, adjustment of the components, and other purposes. This production process is important for improving the quality of our products, and we use chloride in this process. In order to determine how to effectively use the magnesium chloride contained in the dross generated in the treatment process, we began to conduct research and investigations in the 1990s and established a dedicated facility in Shinshiro Plant in 1994. Since then, our recycling business has continued to operate by delivering all dross generated in our plants in Japan to Shinshiro Plant. The magnesium chloride separated from the dross in our dedicated facility is then refined by filtering it to remove impurities. The magnesium chloride solution produced through this process is sold as a product for a variety of applications.

- Application examples

-

- Phosphorus remover for water treatment facilities in chemical plants

- Dust control agent in plants that generate dust

- Antifreezing agent and dust control agent applied to schoolyards, etc.

2-1Aluminium dross

When aluminium scrap is melted, dross rises to the surface of the molten metal. The dross, which is removed to improve the quality of ingots, contains a large amount of aluminium, so we collect as much of the aluminium in it as possible.

Aluminium dross is also generated by die casting manufacturers and casting manufacturers, which are users of our products. We recover aluminium from such dross and turn it into aluminium ingots through component adjustments and refining treatments.

2-2Aluminium ash (aluminium dross for the steel industry)

We are also committed to recycling dross too fine for recovery of aluminium and supplying it to the steel industry, which can use it as an effective resource. It is used, for example, as a temperature elevating agent to reduce energy consumption in steel refining and as a deoxidizer to remove impurities. Our aluminium ash is characterized by a low fluorine content, and it has a good reputation. The overseas bases of the DIK Group are also working to make effective use of aluminium ash, and we launched a business to sell it in the ASEAN region in 2013. In this way, aluminium ash generated as a by-product of aluminium alloy production is reborn as a valuable material through processing and quality control.

Dross Treatment Technology Solutions

Steel Making Additive