ECA2

- Aluminium alloys

- Aluminium alloys for high pressure die casting

- Developed alloys

- Automobiles and motorcycles

- Various on-vehicle parts

- Precision equipment

Features

Eco-friendly aluminium alloy that can be cast even at a low temperature

1

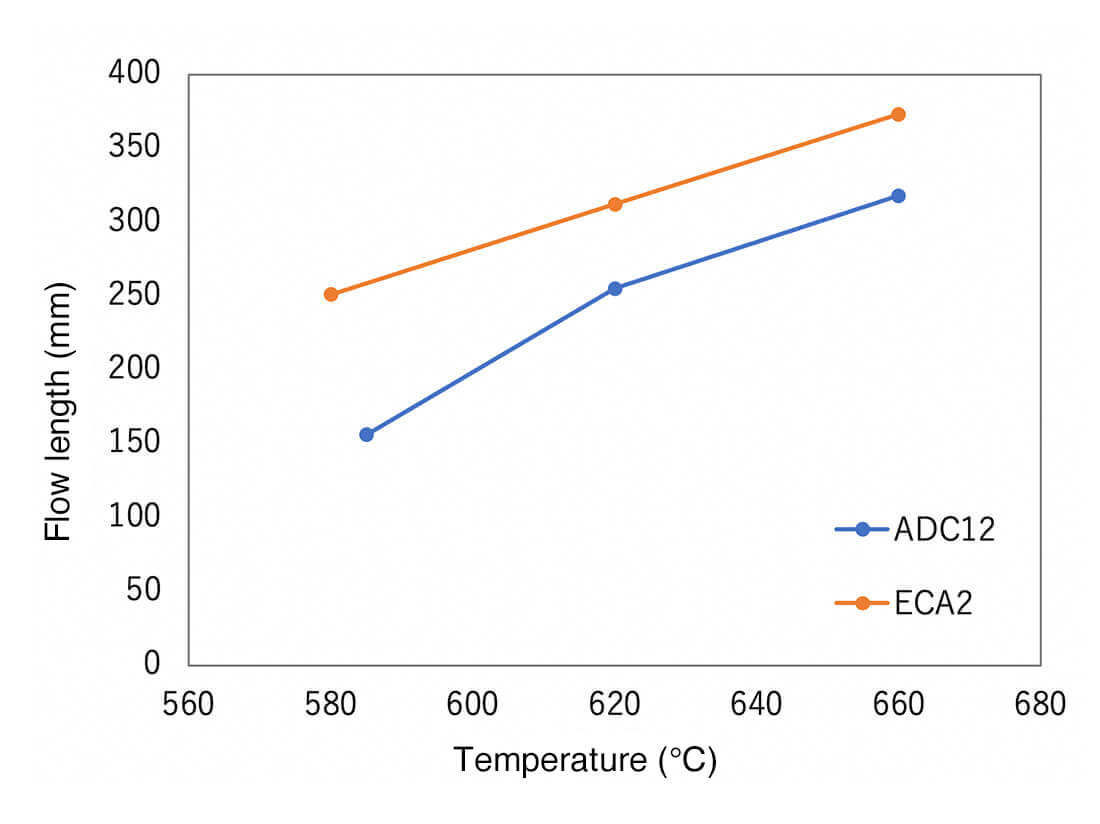

This alloy has higher fluidity than ADC12. (Graph 1)

2

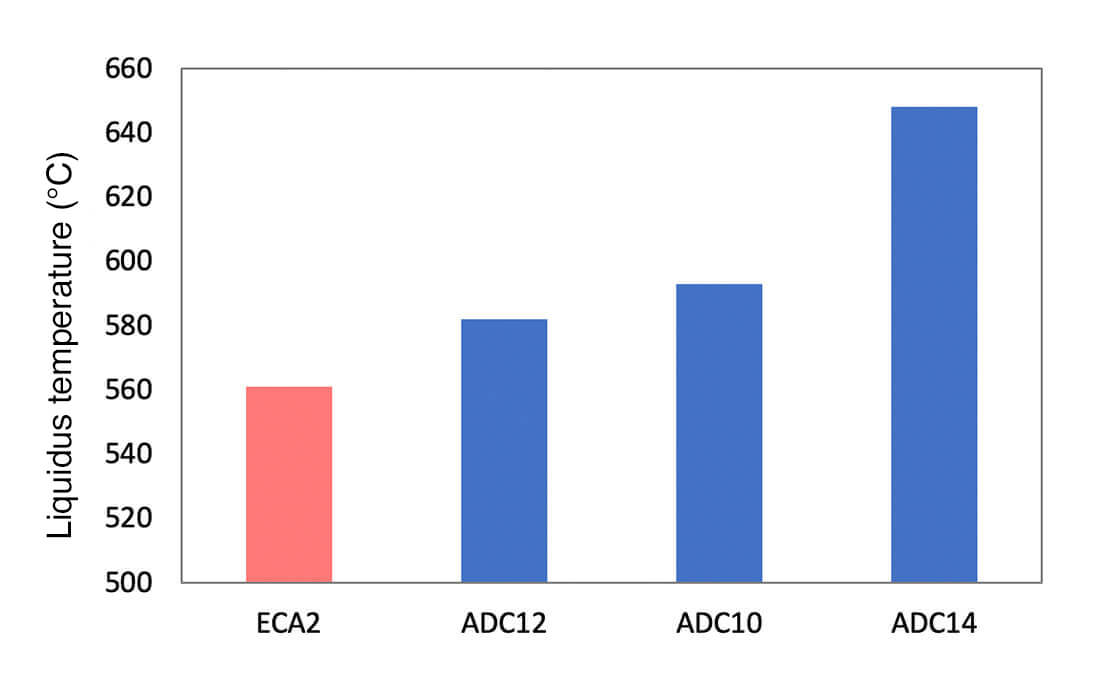

It has a low liquidus temperature (561°C) and can be cast at a low temperature. (Graph 2)

It has a proven track record with respect to die casting at a casting temperature of 600°C.

3

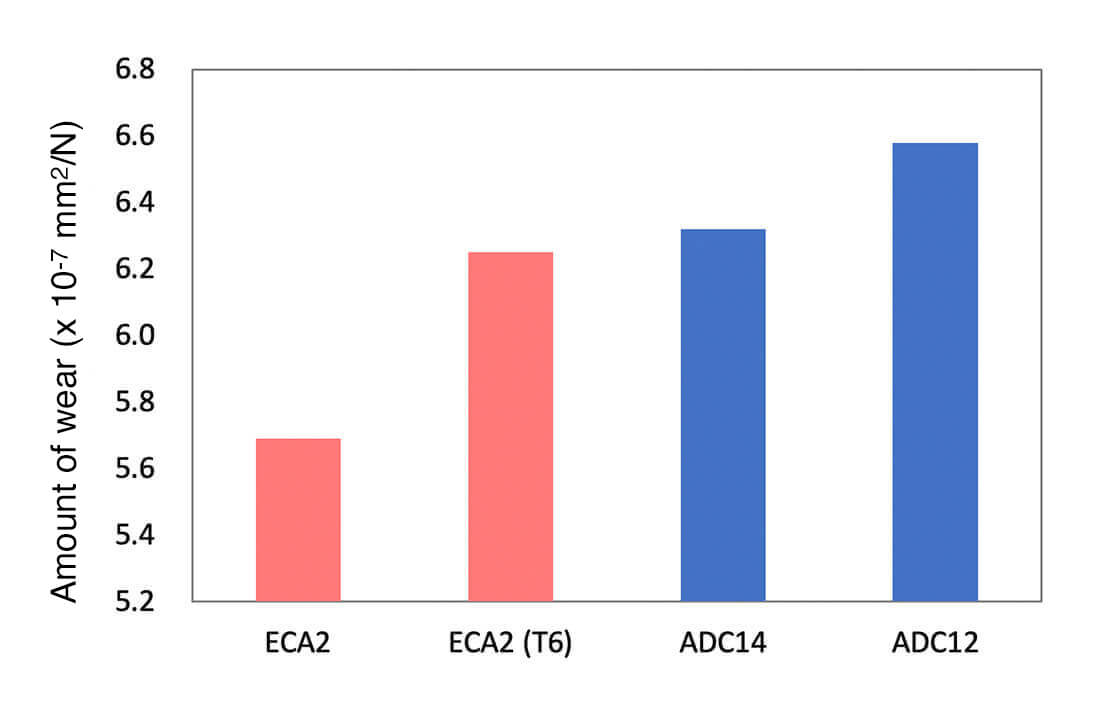

It has excellent wear resistance. (Graph 3)

4

It can be cast at low temperatures to extend the lifespans of dies.

It can be filled at low speeds, and a T6 treatment can be applied by low-speed (laminar flow) filling.

5

Low casting temperatures also reduce the use of mold release agents.

Regarding test molds, this alloy has a track record with respect to casting without the use of mold release agents.

6

It has a higher proof stress than ADC12. (Table 3)

Table 3. Comparison of mechanical properties between ECA2, ADC12, and ADC14

| Alloy name | Casting temperature (°C) | Injection speed (m/s) | Heat treatment | Tensile strength (MPa) | Elongation (%) | 0.2% proof stress (MPa) | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|---|

| ECA2 | 600 | 2 | None (F material) | 346 | 1.3 | 234 | 128 |

| 680 | 0.2 | 500°C x 3 hr water quenching 180°C x 3 hr air cooling (T6) |

423 | 0.7 | 422 | 169 | |

| ADC12 | 680 | 2 | None (F material) | 354 | 3.4 | 184 | 102 |

| ADC14 | 750 | 2 | None (F material) | 293 | 0.5 | 260 | 110 |

Components

Main alloy components (wt. %)

| Cu | Si |

|---|---|

| 7.5 | 10.5 |

ECA2 has been patented.

Remarks

Please note that the figures described in the above technical data are based on our measurements and are not guaranteed.